1D Simulation of Intake Manifold

Suppose you have to design a 600 cc engine, you have no data , how will you start. Benchmarking can help in this case. I took R6 specification and then did 1D Simulation as per my expectation of final power torque curve. Following parameters are not standard of R6, I have changed them based on my 1D Simulation - see other blog for Modeling and Simulation of throttle bore, diffuser, intake manifold, cylinder, timing, exhaust valve.

From Yamaha R6 Engine Specification and initial simulation iterations following parameters haven finalized for our final simulation:-

Description

|

Primary

Parameters

|

Ambient

Temp, Pressure

|

20°C,1atm

|

Throttle

Body

|

Bore

40mm,Idling 5°, WOT 85°,Shaft Dia 10mm

|

Diffuser

Convergent

|

L

250mm,Din 40mm to Dout 20mm,t 5mm, steel

|

Diffuser

Divergent

|

L

250mm, Din 20mm to Dout 60mm,t 5mm, steel

|

Intake

Plenum

|

Design1:

5 Liters, Design2: 3Li, Design3:1Li, Aluminum

|

Manifold

Runner

|

L

260mm,Constant Dia 40,t 5mm, Aluminum

|

Port

Length

|

50

mm, Dia 40mm to 35mm,t 10mm, Aluminum

|

Intake

Valve Dia

|

2Valves

, Dia 27mm

|

Intake

Valve Timing

|

IVO

39 °, IVC 66 °, Max Lift 8.5 mm

|

Cylinder

|

B/S

67/42.5mm,Cr 13,ConRod90.5mm

|

Exhaust

Valve Timing

|

EVO

64 °,EVC 24 °, Max Lift 7.7mm

|

Exhaust

Valve Dia

|

2Valves,

23mm

|

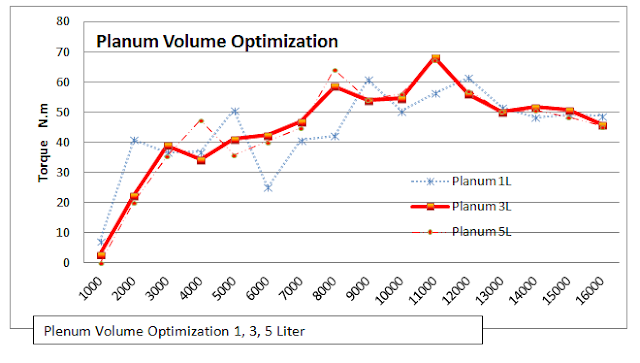

Effect of Plenum of Volume on Torque is

shown in below table. Initially very distinct value is chosen; for further

optimization incremental value for plenum volume will be analyzed.

Conclusion from Above Graph: -As we can see at Plenum Volume 3 Liter, Torque is smooth consequently now we will refine plenum volume near 3L only.

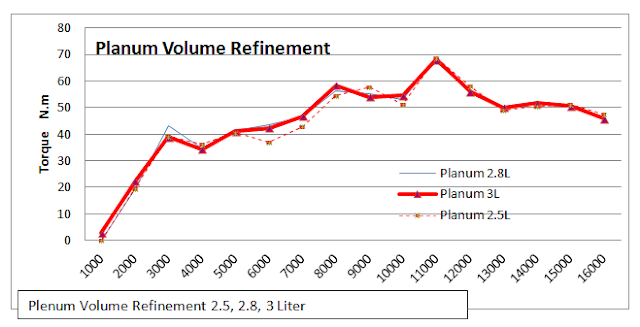

Conclusion from Above Graph: -

2.8 Li Plenum volume gives smooth torque consequently now Runner Cross Section

variation will be simulated for 2.8 Liter plenum volume. Go to next article for simulation of runner.